RLK Coatings Bakersfield - California

Polyurea -Metalizing- Spray Foam Insulation-Mudjacking

Epoxies -Epoxy Injection- Fire Resistant Coatings

Roof & Floor Coatings - Sprayable Ceramics- Concrete Overlays

Serving: Oil & Gas - Agriculture - Industrial - Commercial - Residential

Insulation Oil & Gas

Tank Insulation

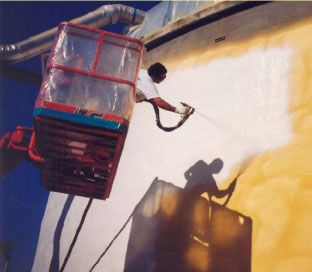

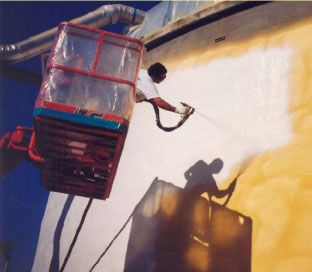

We utilize either a high performance polyurethane foam or a spray applied thin mil coating in our tank insulation process. We'll apply the weight and thickness of foam/thin mil to coating coincide with your insulating requirements.Both allow no corrosion under insulation. For the topcoat, we have a full range of products that can meet your needs whether be aesthetic, cost and/or lifespan dependent.If you been operating your tanks at less than 100 % due to tanks heating up & off gassing this will let you regain full use of your tanks.

Pipeline Insulation/Coatings

Do your pipeline systems look like these? Are your maintenance and recoating costs out of control?

Traditional Method Traditional Method

Once our system is applied, it offers a heat resistant (up to 400 degrees) barrier that does not allow corrosion like traditional cladded insulation products.A 20 mil coating will bring temperatures down from 400 degrees to 140 degrees. Maintenance is much easier and cost effective since technicians do not have to remove cladding before performing work. Also you cannot crush/dent it so your lines will always look good & insulate properly.Additionally, seal and/or pipe failures are easier and safer to locate.The thin mil coating is also great safety item around boilers,Interior steam lines & where ever protection from heat is desired.

Our System

We utilize either a high performance polyurethane foam or a spray applied thin mil coating in our tank insulation process. We'll apply the weight and thickness of foam/thin mil to coating coincide with your insulating requirements.Both allow no corrosion under insulation. For the topcoat, we have a full range of products that can meet your needs whether be aesthetic, cost and/or lifespan dependent.If you been operating your tanks at less than 100 % due to tanks heating up & off gassing this will let you regain full use of your tanks.

Pipeline Insulation/Coatings

Do your pipeline systems look like these? Are your maintenance and recoating costs out of control?

Traditional Method Traditional Method

Once our system is applied, it offers a heat resistant (up to 400 degrees) barrier that does not allow corrosion like traditional cladded insulation products.A 20 mil coating will bring temperatures down from 400 degrees to 140 degrees. Maintenance is much easier and cost effective since technicians do not have to remove cladding before performing work. Also you cannot crush/dent it so your lines will always look good & insulate properly.Additionally, seal and/or pipe failures are easier and safer to locate.The thin mil coating is also great safety item around boilers,Interior steam lines & where ever protection from heat is desired.

Our System